PPM

(Planned Preventative Maintenance)

What is PPM?

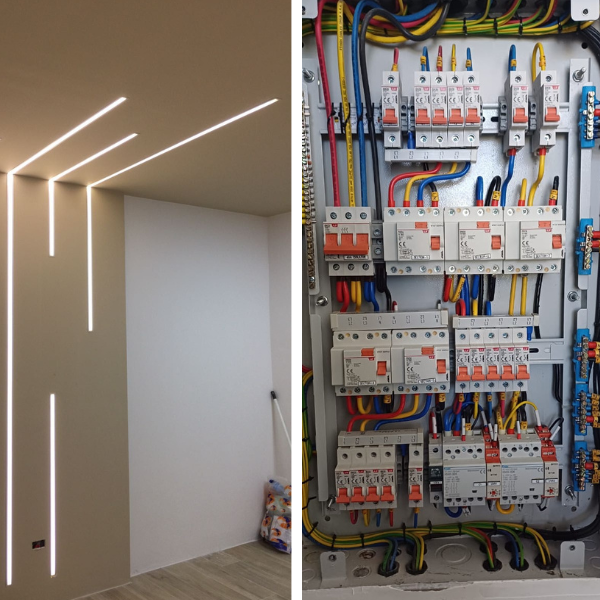

Planned Preventive Maintenance (PPM) is a proactive approach to maintaining CCTV systems, home automation, gate automation, boom barriers,

automatic rolling shutters, and automatic garage doors.

electrical works, LED lighting, motors, control panel boards, and Regular servicing ensure all systems function efficiently, reducing unexpected failures and costly repairs.

?PPM ما هو

الصيانة الوقائية المخططة (PPM) هي نهج استباقي لصيانة أنظمة الدوائر التلفزيونية المغلقة ، والأتمتة المنزلية ، وأتمتة البوابة ، وحواجز ذراع الرافعة

مصاريع الدرفلة الأوتوماتيكية ، وأبواب المرآب الأوتوماتيكية.

تضمن الأعمال الكهربائية وإضاءة LED والمحركات ولوحات لوحة التحكم والخدمة المنتظمة أن جميع الأنظمة تعمل بكفاءة ، مما يقلل من الأعطال غير المتوقعة والإصلاحات المكلفة.

എന്താണ് PPM?

സിസിടിവി സംവിധാനങ്ങൾ, ഹോം ഓട്ടോമേഷൻ, ഗേറ്റ് ഓട്ടോമേഷൻ, ബൂം ബാരിയറുകൾ എന്നിവ പരിപാലിക്കുന്നതിനുള്ള ഒരു സജീവ സമീപനമാണ് ആസൂത്രിത പ്രിവന്റീവ് മെയിന്റനൻസ് (പിപിഎം).

ഓട്ടോമാറ്റിക് റോളിംഗ് ഷട്ടറുകളും ഓട്ടോമാറ്റിക് ഗാരേജ് ഡോറുകളും.

ഇലക്ട്രിക്കൽ ജോലികൾ, എൽഇഡി ലൈറ്റിംഗ്, മോട്ടോറുകൾ, കൺട്രോൾ പാനൽ ബോർഡുകൾ, പതിവ് സേവനം എന്നിവ എല്ലാ സിസ്റ്റങ്ങളും കാര്യക്ഷമമായി പ്രവർത്തിക്കുന്നുവെന്ന് ഉറപ്പാക്കുന്നു, അപ്രതീക്ഷിത പരാജയങ്ങളും ചെലവേറിയ അറ്റകുറ്റപ്പണികളും കുറയ്ക്കുന്നു.

Key Benefits of PPM in Technical Services

CCTV Systems – Prevents camera failures, enhances security, and ensures 24/7 surveillance reliability.

Home Automation – Maintains seamless operation of smart systems, avoiding glitches that disrupt home comfort.

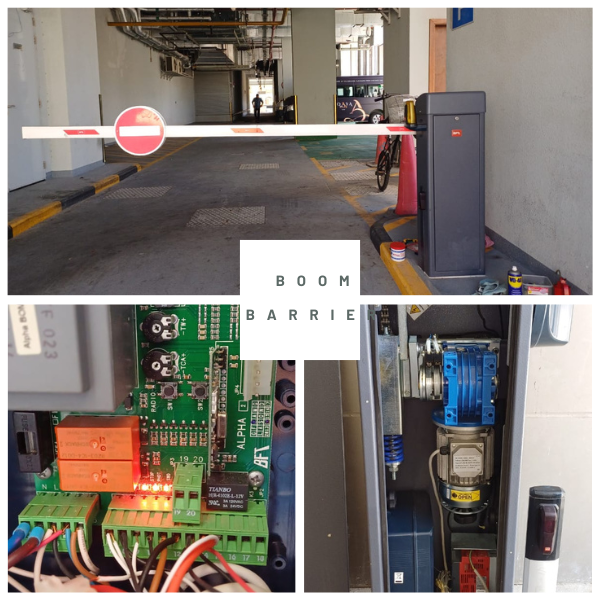

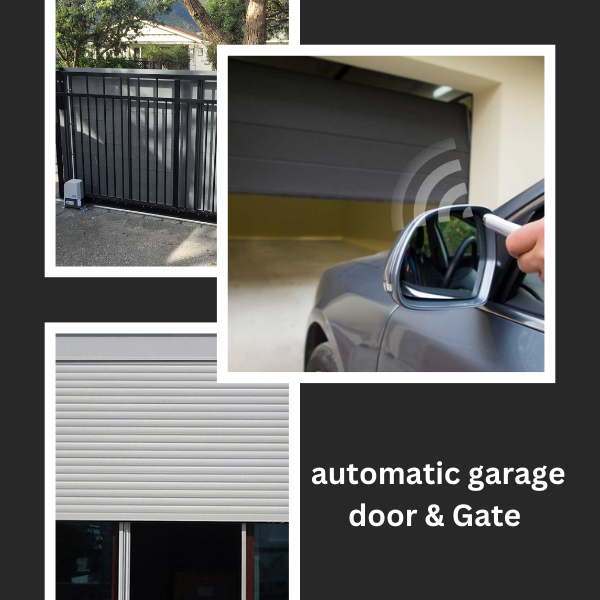

Gate & Boom Barrier Automation – Ensures smooth access control, preventing malfunctions that could compromise security.

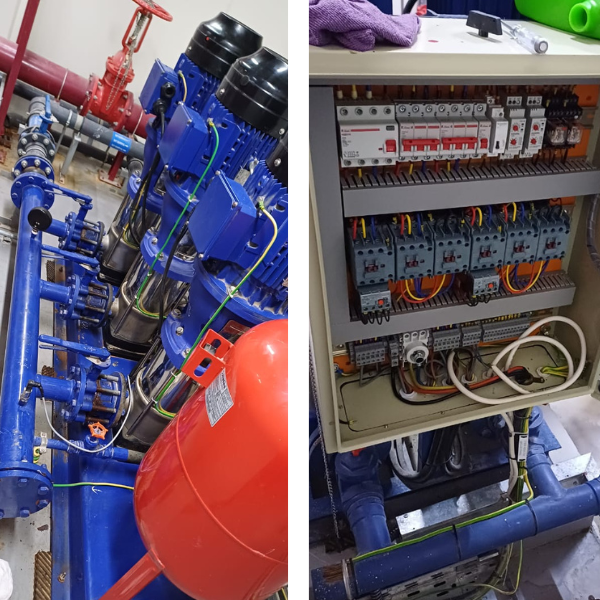

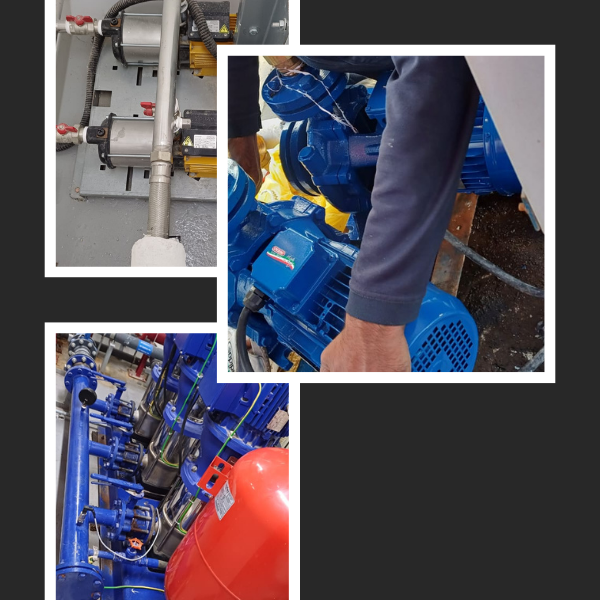

Motors – Keeps motors running efficiently, preventing overheating, wear, and unexpected breakdowns.

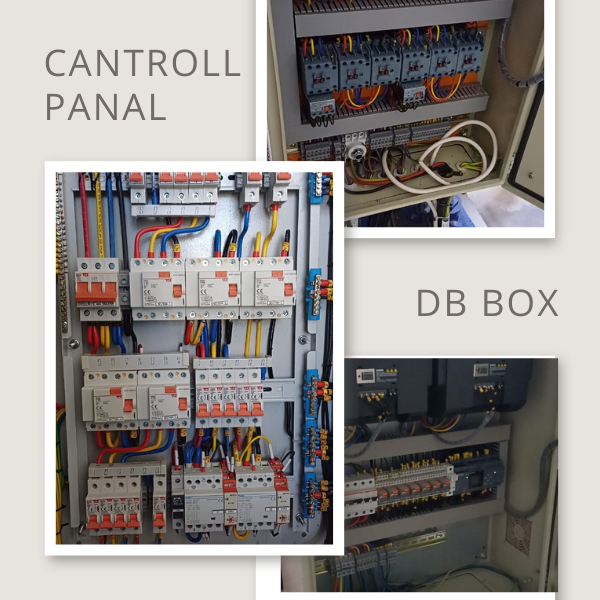

Control Panel Board – Ensures proper wiring, circuit protection, and power distribution to avoid electrical failures.

Automatic Rolling Shutters – Prevents jamming, improves security, and ensures smooth operation with regular lubrication and alignment checks.

Automatic Garage Doors – Maintains motor efficiency, sensor accuracy, and remote control responsiveness to prevent operational failures.

Electrical Works—Maintaining electrical systems in top condition reduces the risk of short circuits, power failures, and fire hazards.

LED Lighting – Extends the lifespan of lighting systems, ensuring energy efficiency and reducing replacement costs.

Minimized Downtime – Scheduled maintenance prevents sudden failures, keeping operations smooth and uninterrupted.

Cost Savings – Regular check-ups help detect minor issues before they turn into expensive repairs.

Compliance & Safety – Ensures adherence to local regulations and industry safety standards, reducing liability risks.

Improved Client Satisfaction – Reliable systems mean fewer complaints and a better customer experience.

الفوائد الرئيسية ل PPM في الخدمات الفنية:

أنظمة الدوائر التلفزيونية المغلقة – تمنع أعطال ، وتعزز الأمان ، وتضمن موثوقيالكاميرا ة المراقبة 24/7.

أتمتة المنزل – يحافظ على التشغيل السلس للأنظمة الذكية ، وتجنب مواطن الخلل التي تعطل الراحة المنزلية.

أتمتة حاجز البوابة وذراع الرافعة – يضمن التحكم السلس في الوصول ، مما يمنع الأعطال التي يمكن أن تعرض الأمان للخطر.

المحركات – يحافظ على تشغيل المحركات بكفاءة ، مما يمنع ارتفاع درجة الحرارة والتآكل والأعطال غير المتوقعة.

لوحة لوحة التحكم – تضمن الأسلاك المناسبة وحماية الدائرة وتوزيع الطاقة لتجنب الأعطال الكهربائية.

مصاريع الدرفلة الأوتوماتيكية – تمنع التشويش ، وتحسن الأمان ، وتضمن التشغيل السلس مع فحوصات التشحيم والمحاذاة المنتظمة.

أبواب المرآب الأوتوماتيكية – تحافظ على كفاءة المحرك ودقة المستشعر واستجابة جهاز التحكم عن بعد لمنع الأعطال التشغيلية.

الأعمال الكهربائية – يقلل الحفاظ على الأنظمة الكهربائية في أفضل حالة من مخاطر حدوث ماس كهربائي وانقطاع التيار الكهربائي ومخاطر الحريق.

إضاءة LED – تطيل عمر أنظمة الإضاءة ، مما يضمن كفاءة الطاقة ويقلل من تكاليف الاستبدال.

تقليل وقت التوقف عن العمل – تمنع الصيانة المجدولة الأعطال المفاجئة ، مما يحافظ على سلاسة العمليات ودون انقطاع.

توفير التكاليف – تساعد الفحوصات المنتظمة في اكتشاف المشكلات البسيطة قبل أن تتحول إلى إصلاحات باهظة الثمن.

الامتثال والسلامة – يضمن الالتزام باللوائح المحلية ومعايير السلامة الصناعية ، مما يقلل من مخاطر المسؤولية.

تحسين رضا العملاء – تعني الأنظمة الموثوقة شكاوى أقل وتجربة أفضل للعملاء.

PPM Checklist for BMS Technician

1️⃣ Visual & Physical Inspection

🔍 Check for dust, dirt, and debris

- Dirt and dust can accumulate on the motor’s surface and cooling vents, causing overheating. Regular cleaning prevents efficiency loss.

🔍 Inspect motor casing for cracks or overheating marks

- Overheating can cause discoloration or burnt marks on the motor housing. Cracks may indicate structural issues.

🔍 Ensure proper alignment between the motor and its load

- Misalignment between the motor and connected equipment can lead to excessive wear, vibration, and energy loss.

2️⃣ Electrical Inspection

⚡ Measure voltage and current draw to ensure proper load balance

- Using a multimeter or clamp meter, check if the voltage and current draw are within the manufacturer’s specifications. Imbalances can damage the motor over time.

⚡ Check for loose or corroded electrical connections

- Loose connections cause resistance, leading to overheating and potential failure. Corroded terminals should be cleaned or replaced.

⚡ Inspect motor terminals for overheating or burn marks

- Overheated terminals can indicate excessive current flow or loose connections. These should be addressed immediately to prevent damage.

3️⃣ Mechanical Inspection

⚙ Check motor bearings for wear and apply lubrication as needed

- Bearings reduce friction and allow smooth rotation. Lack of lubrication can cause friction, noise, and failure.

⚙ Ensure motor shaft alignment with connected machinery

- A misaligned shaft can cause uneven wear and excessive vibration, reducing the motor’s lifespan.

⚙ Test the motor for unusual noise or excessive vibration

- A well-maintained motor should run smoothly. Any unusual noise (grinding, humming, or rattling) may indicate internal damage.

4️⃣ Insulation & Cooling System

🌡 Measure insulation resistance using a Megger test

- A megger test measures the insulation resistance between motor windings and ground. Low resistance indicates deteriorated insulation, leading to short circuits.

🌡 Clean cooling fans and ventilation openings

- Overheating is a common cause of motor failure. Ensure cooling fans and air vents are free from dust and debris to maintain airflow.

🌡 Check the motor’s temperature during operation

- Use an infrared thermometer or temperature gun to check the operating temperature. If it exceeds the rated value, there might be overloading or ventilation issues.

5️⃣ Operational Testing

✅ Start the motor and monitor smooth operation

- The motor should start without delay or excessive current draw. A slow start may indicate capacitor or starter relay issues.

✅ Verify correct rotation direction

- Some motors have a designated rotation direction. Running in the wrong direction can affect equipment performance.

✅ Test motor under load conditions and ensure efficiency

- The motor should operate smoothly under its normal workload. Monitor any overheating, vibrations, or unusual noises.

6️⃣ Safety Checks

⚠ Inspect emergency stop functions

- The emergency stop button must function properly to immediately shut down the motor in case of an emergency.

⚠ Test overload protection devices

- Overload relays protect the motor from excessive current. Test these devices to ensure they trip correctly when needed.

⚠ Ensure proper earthing and grounding

- A well-grounded motor prevents electric shock hazards and protects against electrical surges.

7️⃣ Documentation & Reporting

📋 Log all maintenance activities and findings

- Record the date, time, and details of maintenance performed. This helps in tracking trends and identifying recurring issues.

📋 Record any unusual vibrations, noise, or overheating

- Keeping a detailed log helps diagnose problems before they lead to failures.

📋 Recommend necessary repairs or replacements

- If any component shows signs of wear or failure, recommend corrective actions such as part replacement or realignment.

🔹 Additional PPM for Other Systems

8️⃣ CCTV System Maintenance

📹 Physical Inspection – Ensure cameras are free from dust and aligned properly.

📹 Functionality Testing – Check video clarity, night vision, and motion detection.

📹 Storage & Recording – Ensure footage is being recorded and saved properly.

📹 Power & Connectivity – Verify cables, power sources, and network connectivity.

📹 Software & Security – Update firmware and check access permissions.

9️⃣ Home Automation System Maintenance

🏠 Smart Lighting & Switches – Test response time and automation schedules.

🏠 Sensors & Security – Ensure motion sensors and alarms work correctly.

🏠 Integration & Network – Check cloud sync and mobile app control.

🏠 Power Backup & Firmware – Test battery backups and update firmware.

🔟 Gate Automation & Boom Barrier Maintenance

🚪 Mechanical Inspection – Lubricate hinges, rollers, and check structural integrity.

🚪 Motor & Control System – Inspect motor wiring, power levels, and emergency stop.

🚪 Access Control System – Test remote controls, RFID, and biometric scanners.

🚪 Power & Backup – Ensure UPS and battery backup systems are working.

🔹 Electrical Systems & LED Lighting

💡 Wiring & Connections – Inspect for loose, burned, or corroded wiring.

💡 Load Management – Verify balanced voltage and test circuit breakers.

💡 Lighting Inspection – Ensure LEDs are functioning properly and not flickering.

💡 Surge Protection & Backup – Check surge protectors and UPS for reliability.

“If you have any interest in PPM work at your building or house, you do not need to hesitate to contact us.”

masaratalmubarak@gmail.com

+971567632383

Address

Land DM No 346-499

Property No 191-12-208

Dubai Business Bay

UAE

our office

MK Residency

Calicut

Kerala

India